Having fun?? I hope so.

As always READ to the end BEFORE you start any construction.

Now it is time to fire up the solder melting machine and put together our prototype.

Before we fire up the soldering tools, let's get our parts together. And while we are doing that, we might just as well check out parts clearances for the board.

First thing to do is print out a copy of the board. (I set it to print just the Front Silkscreen and the Back Silk Screens.)

Now I cut it to size and place it on a piece of Styrofoam.

Now take a sharp instrument (I used an push pin) Gently stab each hole but just enough to put a small hole in the paper.

This will make sticking the parts on the fake board much easier.

Now we start placing our parts and checking the clearances. Here is what it looks like.

See why we do this? It looks to me like C-1 on the board is smaller than the .1 uf cap I am using.... SO back to Kicad to change the 'footprint'. And C-1 and R-1 are a bit too close to the chip, so I might just as well move them.

Moo-cho better. Now C-1 is the correct size and it and R-1 have moved up and to the right just a skuntch.

Now since this board will have components on the back, (Orange LEDs and all the connectors) I need to go with a double-sided board.

I just happen to have one on hand, that I was going to use on another part of the project.

Let's go out to the shop and trim it to size and drill some mounting holes. (It's nice to have a full-blown shop)

And here we are with ALL of the components mounted to the prototype.

Although I made the prototype a bit larger than the board, I think the RED LEDs are too close together. I may go back into the board and make that change. Remember, this will mount FACE UP onto the board panel. That's why all the connectors are on the BACK of the board. Aren't I the clever one???

And the back view.

And while we are playing around, let's check the footprints on the main board.

Note to self: "Self, you might want to check footprints BEFORE you spend three hours running traces on the board in KICAD. Oh well, let's correct it and LEARN from it."

OK, here we are again. Let's print 'er and recheck the clearances.

Then I took one of my larger boards out to the shop and cut it down to size.

I drilled some mounting holes in the board and mounted some stand offs. These stand offs help elevate the board when putting long leaded components into place.

Here is how it looks:

I did not have a 7-pin connector, so I used a six pin. (The 7-pin connector does not use all 7 connections, so it's not a big deal)

I also used some .1 headers as a transistor sockets The LEDs and the relays are soldered direct to the board.

The LEDs show power coming to the board. +15 V and -15V.

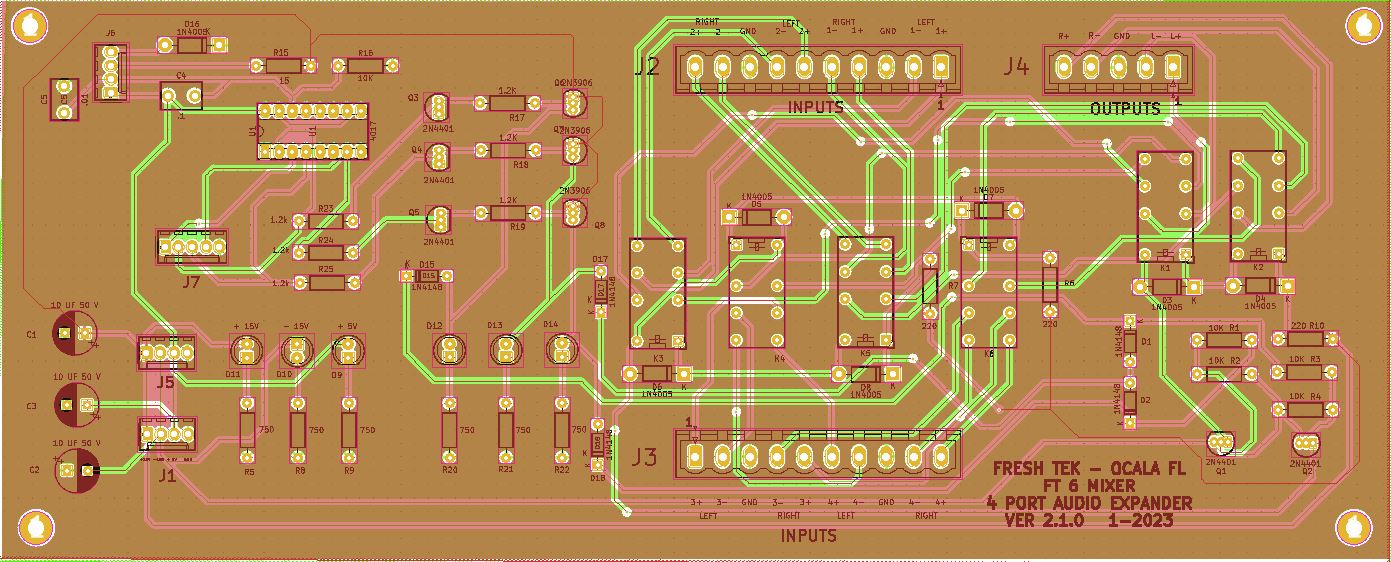

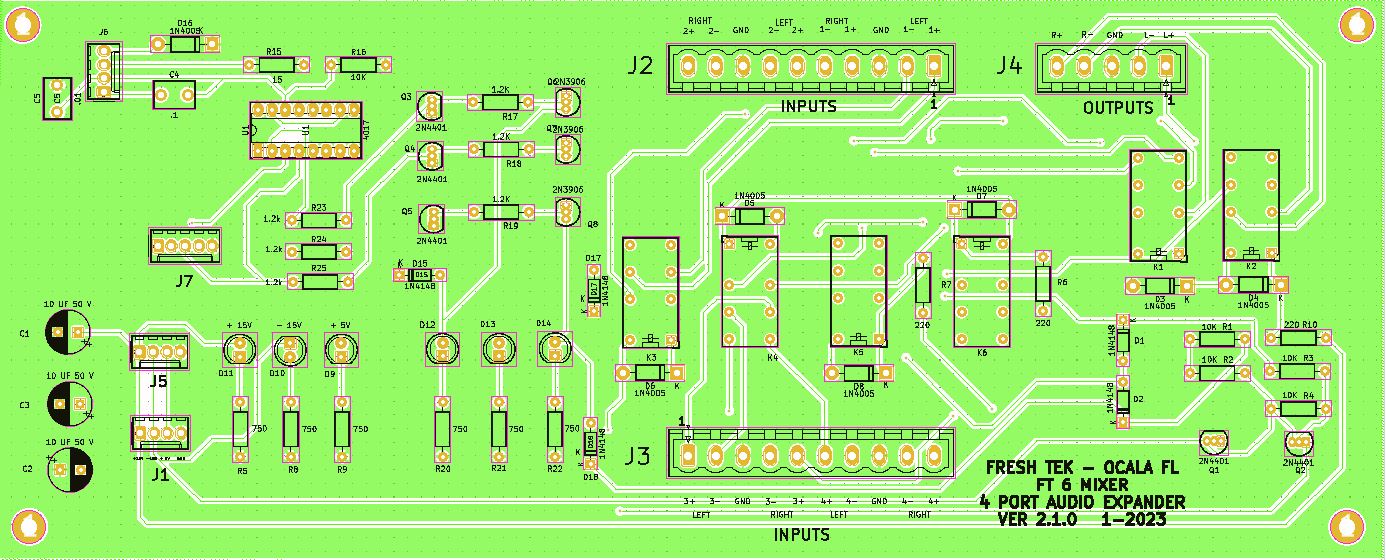

Now we get out our circuit board picture showing the trace layouts.

Using the traces as a guide, we will wire up the prototype.

I started with the audio input and output wiring to and from the relay contacts. Then with an ohm meter, I traced each wire through the unenergized relays to the output.

Once that is confirmed as correct, we move on to the actual electronic part of the schematic.

You can check the relay functions by placing +15 V on the proper pins on J-1.

For the audio checks, you can hook up an audio amplifier to the output and try 4 different audio sources.

I decided that mounting the LED's direct to the board would cause a problem when doing the final mounting. So, I used sockets and external LED's.

That meant I could abandon the idea of connectors on the back of the board. So back to a single board we go.

I spent some time fixing some schematic errors. D-8 and the transistor footprints were backwards.

The Prototype:

The LAST and Final Board version. (Wanna bet?)

-----------------------------------------------------------------------------------------------

Now that the proto type is finished, let's CHANGE IT!!!!!

Let's CHANGE EVERYTHING!!!!!

OH BOY!!!

OK, I know I keep changing things, but as you go along you get new and better ideas. This is why we do mockups, and prototypes. And then we do it again.

And you get to benefit from those ideas and changes.

If you want to build this expander using two boards, you have enough info to do so.

B U T,

I decided to combine the two boards into ONE in order to make mounting easier. (And I have am still undecided on how to mount all of these boards we are building)

SO, here is the schematic:

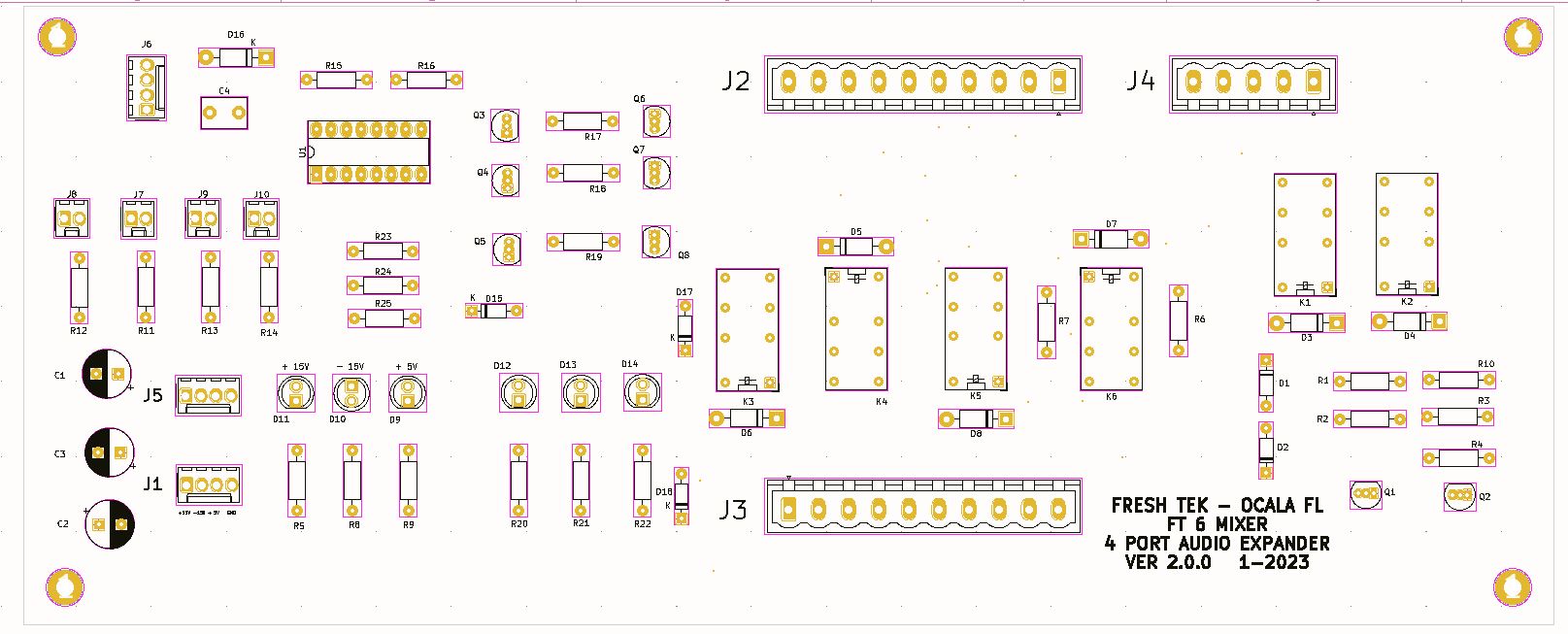

And the Circuit Board:Step 1 : CHECK THE FOOTPRINTS

Once you check the footprints, you can begin construction.

Building the prototype was easy.

Start with mounting ALL the parts on to the board.

Having the parts on the 'footprint" checker made life easy. Just transfer them to the board and solder.

I did make my board a bit LONGER than the footprint version. No reason other than avoiding another cut on the band saw. The final version will be the correct length.

Wire the controller part FIRST. When that is built, TEST IT before moving on.

Here you can see the controller being tested. The RED LEDS are simply "Power ON" showing +5, +15 & -15V. The BLUE represents the three-transistor output feeding the relay circuit.

(Remember: When NO Blue lights are on, the relays are ALL DE-ENERGIZED)

And it worked PERFECTLY.

On to the relay portion.

Once completed I realized that in Position #2 ALL the Blue lights came on. This is due to voltages feeding BACK to the LED's from D1 & D2. This does not cause any issues with the circuits function but may be confusing. So, I added three 1N4148 (D15, D17, & D18) diodes to eliminate the issue.

I also noticed that if left with ANY of the relays energized, the unit would occasionally revert back to position #1. I solved that issue with a 10K pull down resistor from the CLK input of the 4017 to ground.

Here is the circuit working with all the relay drivers and relays connected.

Other issues: The used Dial Co switches did NOT hold up. After some use the contacts started acting up. I thought it was switch bounce, so I added a .01 Cap from the CLK pin 14 of the 4017 to ground. That did not help, so I went back to the Switches I bought from ALL ELECTRONICS.

That means a new prototype switch panel with LED's.

And here it is in action:

I also discovered a problem with the way I mounted the transistors. I have been using a header as a socket, however one of the transistors was intermittent. I will solve that by soldering the transistors directly to the circuit board in the final version.

-----------------------------------------------------------------------------------------------

Now you can wire the relay audio wires. If you are proto typing, doing the audio wires LAST makes the earlier construction easier, as the audio wires do get in the way. Why do I always have to learn the HARD way?

I plan to make 2 of these for the Mixer.

But FIRST, let's show some FINAL pictures and schematic. We have made SO MANY changes during this journey, I wanted you to have the FINAL drawings.

and the FINAL schematic.

I almost forgot!!!! You will need a switch panel. I made several and here is the FINAL version.

The big difference in this board is that the switch is mounted on the reverse side of the board.

Now we can order the boards and get the parts together.

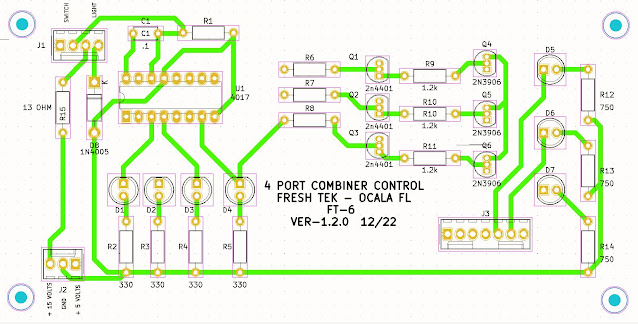

Here are the boards from JLC PRO (Top & Bottom)

Let's start stuffing parts. Start with the power input then test. Move on to the 4017 stepper and test that. Then you should wire the transistors and make sure that part is working correctly. OK so far?? Wire up the Relays and finish it up.

And the finished product side by side with the prototype. (I used the transistors from the prototype.)

A couple of notes here:

I used smaller footprints for the transistors. (MISTAKE) They were a royal PITA to solder. Next time I will use a larger footprint and .1 sockets.

I also had some issues with the input control. Moving a couple of wires around solved that issue.

I also discovered that the footprints for Q-1 & Q-2 were backwards... Reversing the transistors solved that issue. I will have to go into KICAD and fix that problem.

-----------------------------------------------------------------------------------------------

Final thoughts:

I wanted to attempt this board since I was researching how to eliminate the wafer switches. Those switches were also used on the Monitor/Headphone Select boards as well as the Input Select Board.

I found that different switches acted differently. I have a ton of used Dial Co switches from scrapped mixers, so I went through a few of those and chose the best one. But they acted up as well, so I chose a different type of switch. All was well.

(Later Note: I did have a ton of issues with switches not working properly. This was due to contact "bouncing." I tried a number of things that did not work well enough to be stable. I FINALLLY designed a circuit that worked!!! I used that idea on the 'Head Phone/ Monitor select board.

I will ultimately redesign the 4 Port Control board as well.)

Designing something has been on top of my list for months, since I also can use what we learned here on the Monitor and Headphone Select circuits.

Let's take a look at our "TO DO" list and check off the 4 Port COMBINER!!!!!

MIXER PLANNING

1) POWER SUPPLIES

+/- 15 VDC XMFR 1

+/- 7.5 V DC XMFR 1

+ 5.0 VDC (CLOCK/TIMERS) XMFR 2 OR COMMERICAL UNIT

SCHEMATICS

CIR BOARDS

CABINET

2) TIMER / CLOCK - SEPERATE UNITS FROM MIXER DUE TO SPACE LIMITS

12 HOUR MOD 60 MOD 60 MOD 12

24 HOUR MOD 60 MOD 60 MOD 23

TIMER UNIT

RE-SET PANEL

DISPLAY BOARD SCHEMATIC CIR BOARD

MAIN BOARD SCHEMATIC CIR BOARD

60 SEC/MIN MOD SCHEMATIC CIR BOARD

23 HOUR MOD SCHEMATIC CIR BOARD

12 HOUR MOD SCHEMATIC CIR BOARD

CABINET

PROTO TYPE

FINAL

3) HEADPHONE AMPLIFIER

DESIGN

SCHEMATIC

PROTO TYPE

CIRCUIT BOARD

4) CUE AMPLIFIER

CAN ALSO USE AS A TEST AMP WHILE BUILDING AUDIO BOARDS

DESIGN

SCHEMATICS

PROTO TYPE

CIRCUIT BOARDS

5) POWER AMPLIFIER (REPLACES TASCAM PA-30)

DESIGN

SCHEMATICS

PROTO TYPE

CIRCUIT BOARDS

6) OUTPUT BOARD

DESIGN

SCHEMATICS

PROTO TYPE

CIRCUIT BOARDS

7) MONITOR SELECT

DESIGN

AVOID OLD STYLE SWITCHES, USE DIGITAL

SCHEMATIC

PROTO TYPE

CIR. BOARD

8) PGM / AUD / MONO SELECT

DESIGN

AVOID OLD STYLE SWITCHES, USE DIGITAL

SCHEMATIC

PROTO TYPE

CIR. BOARD

9) INPUT SELECT

DESIGN

AVOID OLD STYLE SWITCHES, USE DIGITAL

SCHEMATIC

PROTO TYPE

CIR. BOARD

10) AUDIO INPUT BOARD

DESIGN

RS-12 VERSION

SCHEMATIC

PROTO TYPE - NOT DOING A PROTO TYPE

CIR. BOARD

11) MONITOR BOARD

DESIGN BASED ON MONITOR SELECT DESIGN

SCHEMATIC

PROTO TYPE

CIR. BOARD

12) EXTERNAL MONITOR BOARD

DESIGN

SCHEMATIC

PROTO TYPE

CIR BOARD

13) VU METER BOARD - SEPERATE UNIT ON SHELF

ONLY USED BECAUSE IT IS ALREADY BUILT

14) LED METERING - ON BOARD

USE RS-12 CIRCUIT REG LED'S OR BAR GRAPHS ????

SCHEMATICS

PROTO TYPE

CIRCUIT BOARD

15) D.A. AMPLIFIER

DESIGN

SCHEMATIC

PROTO TYPE

CIR BOARD

16) 4 PORT EXPANDER BOARD

DESIGN

SCHEMATIC

PROTO TYPE

CIR BOARD

17) POWER SUPPLY DISTRIBUTION BOARD ??

MAY BE NEEDED WITH MULTIPLE BOARDS ??

---------------------------------------------------------------------------------------------------------------------------

Now we can move onto the next part of our project !!! CHAPTER 13 - - - CLOCK/TIMER - - THE FINAL BUILD OUT See you then.

God Speed, Mother Nature.

No comments:

Post a Comment