Now that the two clocks are finished, let's move on to the TIMER.

It is the easiest to build.

We decided on ONE board for this timer that will go inside the console itself.

We also decided on smaller Seven Segment Displays (.54" vs the 1" we used on the clocks.)

There is no need for a controller, as all we will be doing is re-setting the timer to 00:00:00 and let it count.

For a reset, our console module will provide a "HIGH" when ever you push the Channel Button. (More on this later).

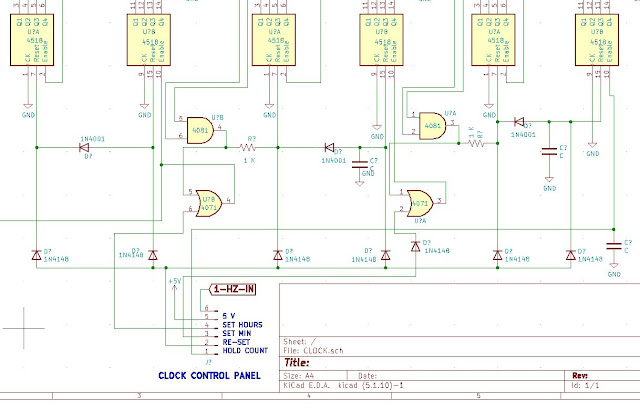

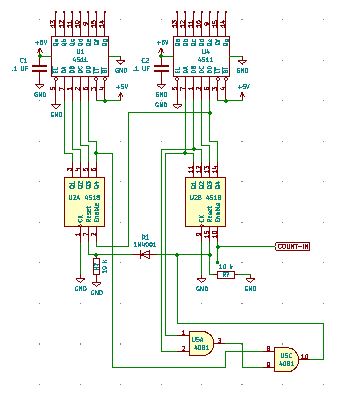

So here is the diagram for the Timer.

The timer is re-set via a relay that closes when it receives a 'high' (1) from the console. The relay contact goes though 4 diodes that will feed a momentary +5 V to the re-set pins.

Easy Peazy. Bob's your uncle.

You build this the same way that you made the Clocks. Place the components, run the busses, and then wire it up.

Don't forget to TEST as you go along.

Everything 'should' work as designed. If so, let's go ahead and order the circuit board from JLC Pro.

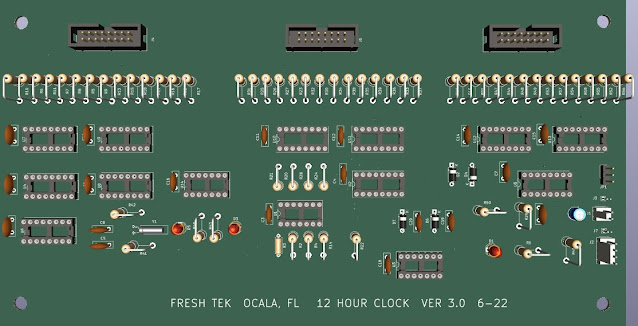

Here is the blank board we got.

Let's stuff some parts, starting with the counter circuit and the seconds part of the timer.When that is verified as working, move onto the seconds section, then the minutes.

There you go, one timer ready to mount in the Mixer Panel.We will now set this aside, and forge ahead.

-----------------------------------------------------------------------------------------------------------------------

Some final thoughts on the clock/timer.

It was hard to get it to come together, but well worth the effort.

Yes, I could have used a PIC/PUC or whatever they are called. Or an Arduino. Or even a programmable chip.

But I love CMOS and I am an old fart.

I ran into on LARGE issues with the finished board. When I hit the "reset", all the digits returned to 'zero" EXCEPT for the 'minutes' digit. It would always land on "1".

So I went back to the bread board to see if I could figure it out. For some reason, adding a resistor to the output of the 4018 solved the issue. I also added a couple of diodes. (The schematics and pictures do MATCH the fixed version.

And yes, I had a few failures and changes in the designs.

But now I have 2 digital clocks in my Ham Shack. (one set to GMT, the other set to LOCAL time)

And a timer for the console.

I learned and relearned a lot of things doing this phase.

But I am glad it's over.

I hope you got as much out of it as I.

So now we have our clocks and timer completed and "running like a clock', we will move on.

It's time to check the clock and timer off of our Planning List.

MIXER PLANNING

1) POWER SUPPLIES

+/- 15 VDC XMFR 1

+/- 7.5 V DC XMFR 1

+ 5.0 VDC (CLOCK/TIMERS) XMFR 2 OR COMMERICAL UNIT

SCHEMATICS

CIR BOARDS

CABINET

2) TIMER / CLOCK - SEPERATE UNITS FROM MIXER DUE TO SPACE LIMITS

12 HOUR MOD 60 MOD 60 MOD 12

24 HOUR MOD 60 MOD 60 MOD 23

TIMER UNIT

RE-SET PANEL

DISPLAY BOARD SCHEMATIC CIR BOARD

MAIN BOARD SCHEMATIC CIR BOARD

60 SEC/MIN MOD SCHEMATIC CIR BOARD

23 HOUR MOD SCHEMATIC CIR BOARD

12 HOUR MOD SCHEMATIC CIR BOARD

CABINET

PROTO TYPE

FINAL

3) HEADPHONE AMPLIFIER

DESIGN

SCHEMATIC

PROTO TYPE

CIRCUIT BOARD

4) CUE AMPLIFIER

CAN ALSO USE AS A TEST AMP WHILE BUILDING AUDIO BOARDS

DESIGN

SCHEMATICS

PROTO TYPE

CIRCUIT BOARDS

5) POWER AMPLIFIER (REPLACES TASCAM PA-30)

DESIGN

SCHEMATICS

PROTO TYPE

CIRCUIT BOARDS

6) OUTPUT BOARD

DESIGN

SCHEMATICS

PROTO TYPE

CIRCUIT BOARDS

7) MONITOR SELECT

DESIGN

AVOID OLD STYLE SWITCHES, USE DIGITAL

SCHEMATIC

PROTO TYPE

CIR. BOARD

8) PGM / AUD / MONO SELECT

DESIGN

AVOID OLD STYLE SWITCHES, USE DIGITAL

SCHEMATIC

PROTO TYPE

CIR. BOARD

9) INPUT SELECT

DESIGN

AVOID OLD STYLE SWITCHES, USE DIGITAL

SCHEMATIC

PROTO TYPE

CIR. BOARD

10) AUDIO INPUT BOARD

DESIGN

RS-12 VERSION

SCHEMATIC

PROTO TYPE - NOT DOING A PROTO TYPE

CIR. BOARD

11) MONITOR BOARD

DESIGN BASED ON MONITOR SELECT DESIGN

SCHEMATIC

PROTO TYPE

CIR. BOARD

12) EXTERNAL MONITOR BOARD

DESIGN

SCHEMATIC

PROTO TYPE

CIR BOARD

13) VU METER BOARD - SEPERATE UNIT ON SHELF

ONLY USED BECAUSE IT IS ALREADY BUILT

14) LED METERING - ON BOARD

USE RS-12 CIRCUIT REG LED'S OR BAR GRAPHS ????

SCHEMATICS

PROTO TYPE

CIRCUIT BOARD

15) D.A. AMPLIFIER

DESIGN

SCHEMATIC

PROTO TYPE

CIR BOARD

16) 4 PORT EXPANDER BOARD

DESIGN

SCHEMATIC

PROTO TYPE

CIR BOARD

17) POWER SUPPLY DISTRIBUTION BOARD ??

MAY BE NEEDED WITH MULTIPLE BOARDS ??

YEAH, Number 2 is completed !!!!!!

Coming up next on "Let's Build An Audio Console"-------- We were going to do an Audio Amplifier next, but changed our minds.

I think we may move onto the audio INPUT cards and a way to feed 4 stereo inputs into ONE Input.

Hope you come along.

God Speed, Mother Nature.