Let's talk about power supplies. (I always try to start with the easy ones.)

-----------------------------------------------------------------------------------

NOTE: Make sure your read ALL the way to the end BEFORE you start building. Numerious design changes were made along the way. It was a fun journey, and a great learning experience,

-----------------------------------------------------------------------------------

The RS 6 & 12 series of consoles used an off the shelf +/- 15 volt supply from CONDOR.

The RS 18 & 24 added an additional 15 volt supply to handle the extra load.

All the consoles in the line used a Radio Systems +/- 7.5 VOLT SUPPLY

So let's pitch that idea and come up with something that will work, without breaking the bank. And that is why we are making our own. Plus you will learn how a Power Supply works.

Back in the day, I did build one of these and it ran perfect for over 2 years. The only "Off The Shelf" power supply was for the 5 volt cock/timer.

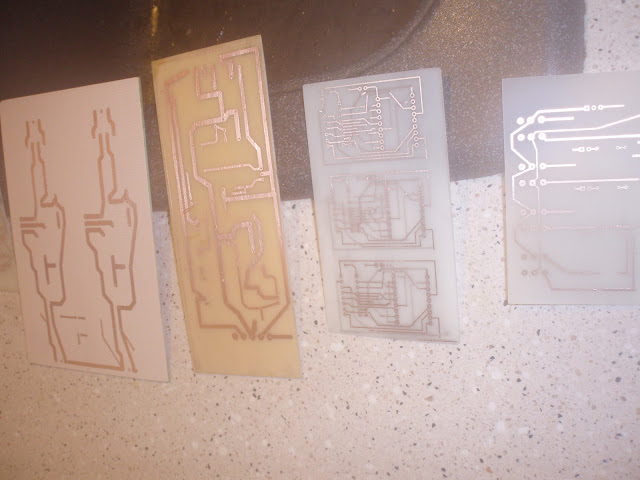

LEFT TO RIGHT - POWER TRANSFORMER +/- 15 VOLT SUPPLY

TOP LEFT - BARRIER STRIP, FOR POWER IN AND OUTPUTS

TOP CENTER - FUSES / ON-OFF SWITCH AND 110 V INDICATOR

RIGHT SIDE TOP - OFF THE SHELF 5 VOLT SUPPLY

RIGHT MIDDLE - +/- 7.5 SUPPLY

BOTTOM - HEAT SINK

Here are some shots of that Power Supply under construction (I wish now I would have saved that P. Supply.)

No, the holes are not on the wrong side. The plexi glass front is turned over.

Yes, I did change the Power Transformer in the final version

-----------------------------------------------------------------------------------

Now that we have talked about what I did, let's do something.

So, now let's begin.

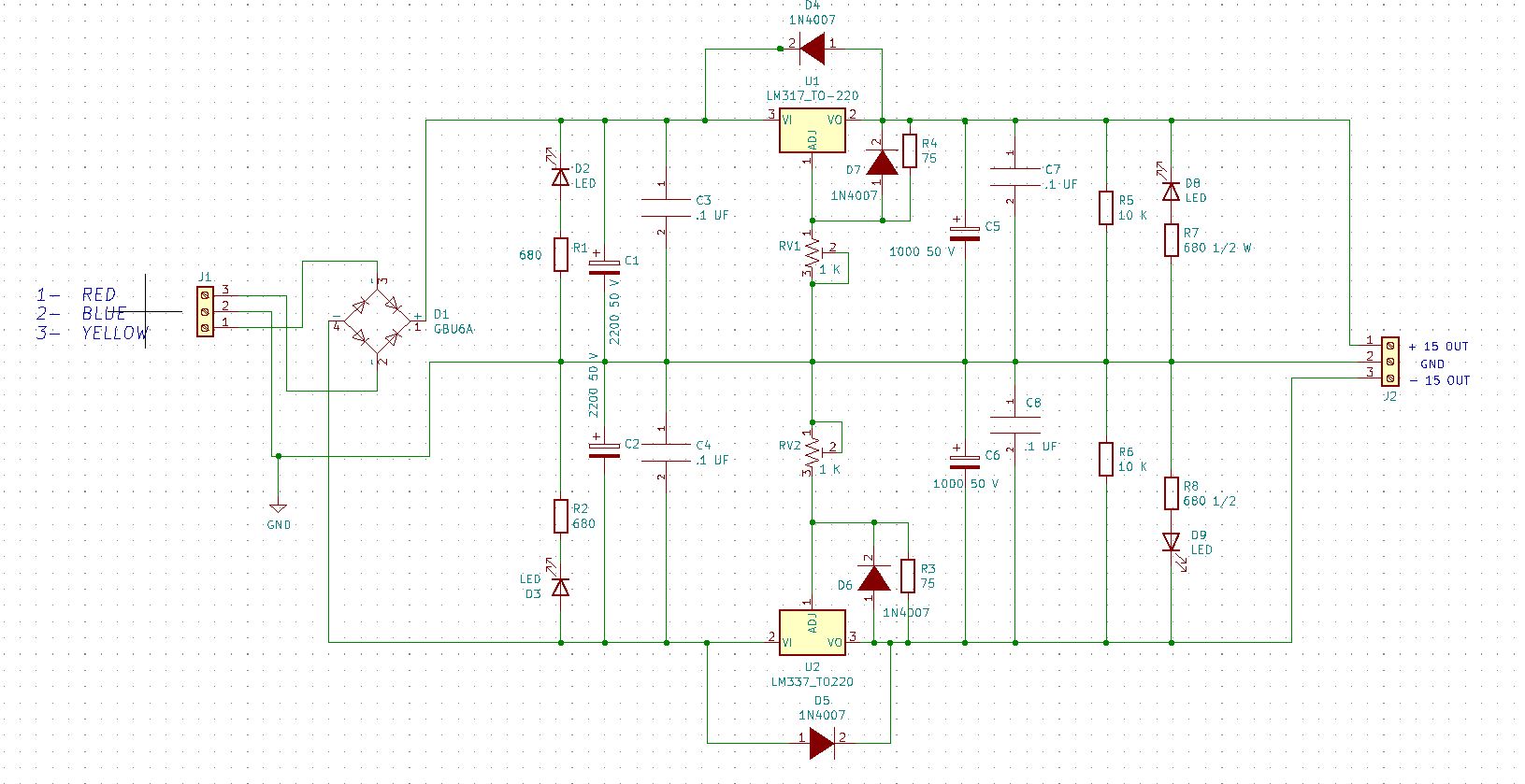

Let's take a look at the +/- 15 Volt supply.

The 'heart' of the Power Supply is the use of adjustable regulators. It takes a few more parts, but is well worth the extra time and money.

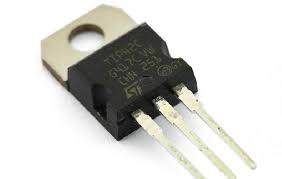

When designing this POWER SUPPLY, I ran into one HUGE roadblock. The regulators I used in my original Power Supply (2005) are now obsolete. I did find them available, for a down town price of $74.00 EACH. So I started looking at various designs using a small regulator teamed up with a large (and inexpensive) transistor that could handle the current (As long as it was properly heat-sinked.)

I am in the process of building the proto type for testing.

(results) - Not good. I found a circuit using a 2N3055 transistor following the LM317 regulator. That worked well, but I never found a circuit to use with a LM337.

So back to researching.......

In looking at the data sheets, the TO-220 version of these regulators spec in at 1.5 AMPS of output current. (Same as the TO-3 version.)

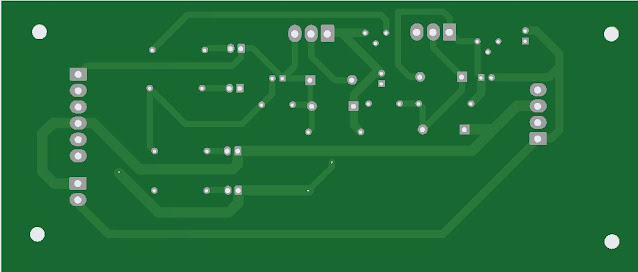

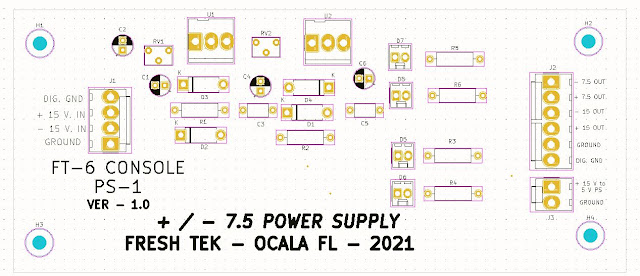

Various filters and diode protection is also in place. The 7.5 volts is sent to J-2

The input 15 V is also routed to J-2.

The LED's show voltage as present at J-2 and is a good indication that the unit is functioning properly.

This will give you outputs of +15 , -15, +7.5, and - 7.5.

We have also added a +15 V output to go to a 5 V power supply board. More on that later.

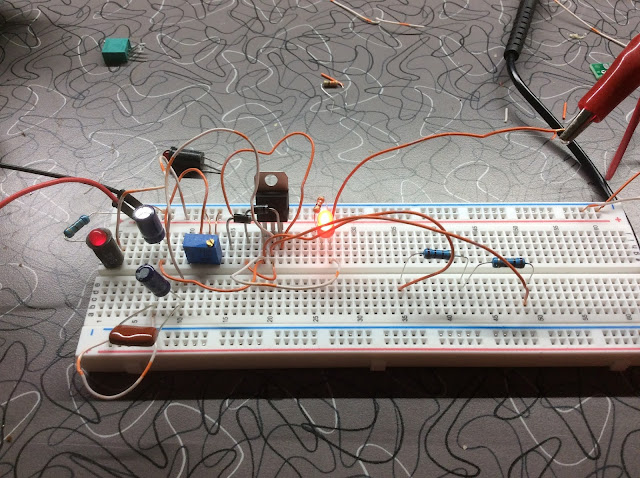

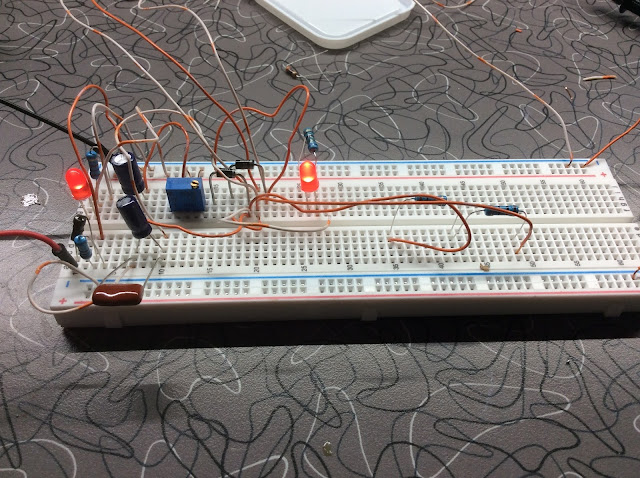

Let's breadboard this puppy and see if it works as designed. We can also make any component and value changes.

Then we can finalize the schematic and update the circuit board art if needed.

Here is the circuit for the -+ 7.5 circuit. (I know it doesn't look very pretty, BUT will it work ??)

Out to the workshop to see if I can find a piece of aluminum to use as a heat sink. I found one that was left over from a previous project.

So lets take the Voltage regulator out of the breadboard and get them mounted. (YOU MUST INSULATE THE REGULATOR FROM THE HEAT INK)

Now let's take a look at the parts list, so you can make your own power supply

C-1 22 UF 50 V

C-2 100 UF 25 V

C-3 .1 UF FILM

C-4 22 UF 50 V

C-5 .1 UF FILM

C-6 100 UF 25 V

D-1 DIODE 1N4005

D-2 DIODE 1N4005

D-3 DIODE 1N4005

D-4 DIODE 1N4005

D-5 5 MM LED

D-6 5 MM LED

D-7 5 MM LED

D-8 5 MM LED

J-1 SCREW CONNECTOR 3 POS

J-2 SCREW CONNECTOR 6 POS

J-3 SCREW CONNECTOR 2 POS

R-1 75 OHM

R-2 75 OHM

R-3 680 OHMS 1/2 WATT

R-4 680 OHMS 1/2 WATT

R-5 330 OHM 1/4 WATT

R-6 330 OHM 1/4 WATT

RV-1 TRIM POT 1 K

RV-2 TRIM POT 1 K

U-1 LM 317 REGULATOR

U-2 LM 337 REGULATOR

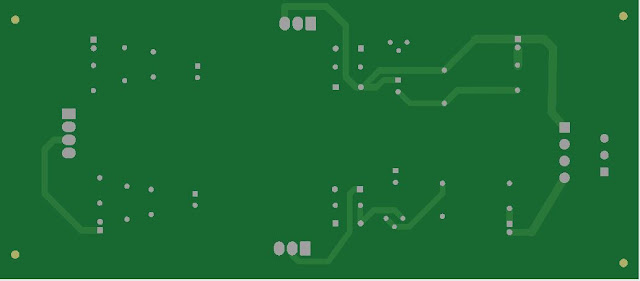

To Circuit Board or or not to Circuit Board.

I used to be a member of the 'perf board clan'. Then I tried to make my own boards at home using a Laser Printer and a modified laminating machine. The simple boards came out fine, but I never could master the complexities of more complicated boards.

But how would I do this board ???

Fortunately, many advancements have been made, allowing us to purchase professionally made boards produced at a reasonable cost.

That's the route I am taking for this project.

There is software available to make this easier.

I use KI-CAD . (This will not be a tutorial in how to use KI-CAD. You are on your own.) I will say that I tested several others and thought KI-CAD to be the best. I am still learning it.

HELPFUL HINT - One bit of advice. Before you order your boards, print it out on paper. I tape it to some Styrofoam and place the parts. This way I can check footprints and clearances.(NOTE:- I built a +5 volt supply for the clocks using the 7.5 Volt design. The only difference is I ended up using a 100 ohm resistor in place of R-1)

C-1 22 UF 35 V

C-2 .1 UF FILM

C-3 .1 UF FILM

C-4 1000 UF 50 V

D-1 5 MM LED

D-2 1N4005 DIODE

D-3 1N4005 DIODE

D-4 5 MM LED

J-1 3 LUG SCREW TERM STRIP

J-2 3 LUG SCREW TERM STRIP

R-1 680 OHMS 1/2 WATT

R-2 100 OHMS 1/4 WATT

R-3 330 OHMS 1/4 WATT

RV1 TRIM POT 1 K

U-1 LM317 Regulator

How about the FINAL Parts List for the +/- 15 Volt Supply ??

And the board for the Master Power Supply. The Regulator I.C. is mounted to a temporary Heat Sink. The clip leads provide the output voltage to a Meter and to the Timer. The LED's show the Input and the Output Power.

FINAL PARTS LIST

POWER SUPPLY

------------------------------------------------------------------------

+/- 15VDC POWER SUPPLY

2 - C1, C2 - 2200UF 50V Elect Capacitor

JAMECO 158432

4 - C3, C4, C7, C8 - .1UF Disc Capacitor

AMAZON .07

2 - C5, C6 - 1000UF 50V Elect Capacitor

JAMECO 609553

1 - D1 - Diode Bridge 35V Vrms,6.0A

MOUSER 512-GBU6A

4 - D2, D3, D8, D9 - LED 5mm

AMAZON .07

4 - D2S, D3S, D8S, D9S - Connector 2 Pin Molex .1 2.54mm

DIGI KEY WM19468-ND .28

DIGI KEY WM2601-ND .18

4 - D4, D5, D6, D7 - Diode 1N4007

JAMECO 36011

1 - J1 - 01x03 Screw Terminal 3.96mm

JAMECO 2120655

1 - J2 - 01x04 Connector Molex 3.96mm Horiz.

ALL ELECT CON-394

2 - R1, R2, R7, R8 - 680 ohm 1/4 WATT Resistor

ALL ELECT 293-680

2 - R3, R4 - 75 ohm 1/4 WATT Resistor

JAMECO 293-75

2 - R5, R6 - 10K 1/4 WATT Resistor

ALL ELECT. 291-10K

2 - RV1, RV2 - 1K Trim Potentiometer

ALL ELECT. MTPS 1K

1 - U1 - LM317 TO220 1.5A +35V Adjustable Linear Regulator

JAMECO 23579

1 - U1S - 01x03 Male Connector Molex 3.96mm

JAMECO 879887 .35

JAMECO 463435 .15

1 - U2 - LM337 TO220 1.5A -35v Adjustable Linear Regulator

JAMECO 23819

1 - U2S - 01x03 Male Connector Molex 3.96mm

JAMECO 879887 .35

JAMECO 463435 .15

1 - CB1 - CIRCUIT BOARD - JLC PRO

-------------------------------------------------------------------------

+/- 7.5 VDC POWER SUPPLY

1 - C1, C4 - 22UF 50V Elect Capacitor

JAMECO 93739 .17

2 - C2, C6 - 100UF 25V Elect Capacitor

JAMECO 93833 .49

2 - C3, C5 - .1UF Disc Capacitor

AMAZON * .07

4 - D1, D2, D3, D4 - 1N4005 Diode 600V 1A General Purpose Rectifier

ALL ELECT 1N4005 .13

4 - D5, D6, D7, D8 - LED .5mm

AMAZON * .07

4 - D5S, D6S, D7S, D8S - Connector 2 Pin Molex .1 2.54mm

JAMECO 232266 .15

JAMECO 234704 .12

1 - J1 - 01x04 Connector Molex 3.96mm Horiz.

DIGI KEY WM4642-ND .53

DIGI KEY WM18815-ND .32

1 - J2 - 01x06 Connector Molex 3.96mm Horiz.

DIGI KEY WM4644-ND .70

DIGI KEY WM19505-ND .43

1 - J3 - 01x02 Screw Terminal 3.96mm Horiz.

AMAZON *

2 - R1, R2 - 220 ohm 1/2 WATT Resistor

JAMECO 331343 .10

2 - R3, R4 - 680 ohm 1/2 WATT Resistor

JAMECO 661466 .10

2 - R5, R6 - 330 ohm 1/4 WATT Resistor

JAMECO 690742 .06

2 - RV1, RV2 - 2K Trim Potentiometer

JAMECO 240581 1.95

1 - U1 - LM317 TO220 1.5A +35V Adjustable Linear Regulator

JAMECO 23579

1 - U1S - 01x03 Male Connector Molex 3.96mm

JAMECO 879887 .35

JAMECO 463435 .15

1 - U2 - LM337 TO220 1.5A -35v Adjustable Linear Regulator

JAMECO 23819

1 - U2S - 01x03 Male Connector Molex 3.96mm

JAMECO 879887 .35

JAMECO 463435 .15

1 - CB2 - CIRCUIT BOARD - JLC PRO

---------------------------------------------------------

+ 5 VDC POWER SUPPLY

1 - C1 - 22UF 35V Elect Capacitor

JAMECO 158327 .17

2 - C2, C3 - .1UF Disc Capacitor

AMAZON * .07

2 - C4, C5 - 1000UF 50V Elect Capacitor

JAMECO 609553 .89

2 - D1, D4 - LED .5mm

AMAZON * .07

2 - D1, D4 - Connector 2 Pin Molex .1 2.54mm

JAMECO 232266 .15

JAMECO 234704 .12

2 - D2, D3 - 1N4005 Diode 600V 1A General Purpose Rectifier

JAMECO 76988 .09

2 - J1, J2 - 01x02 Male Connector Molex 3.96mm Horiz.

DIGI KEY WM10165-ND .46

DIGI KEY WM18813-ND .19

1 - R1 - 680 ohm 1/2 WATT Resistor

JAMECO 661466 .10

1 - R2 - 220 ohm 1/4 WATT Resistor

DIDGI KEY CF14JT150RCT-ND .10

1 - R3 - 330 ohm 1/4 WATT Resistor

JAMECO 661386 .10

1 - RV1 - 2K Trim Potentiometer

JAMECO 240573 1.95

1 - U1 - LM317 TO220 1.5A 35V Adjustable Linear Regulator

JAMECO 23579

1 - U1S - 01x03 Male Connector Molex 3.96mm

JAMECO 879887 .35

JAMECO 463435 .15

1 - 1 - CB3 - CIRCUIT BOARD - JLC PRO

------------------------------------------------------------

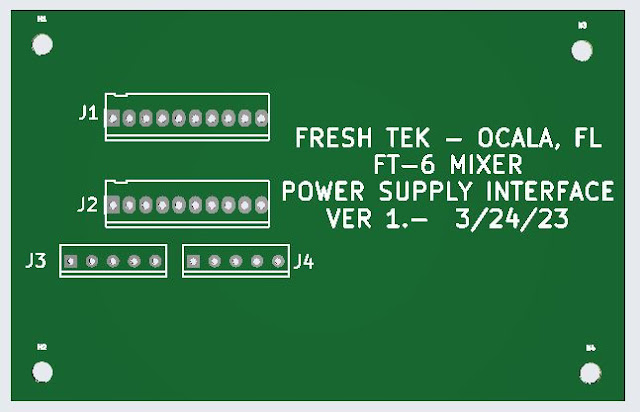

INTERFACE BOARD

2 - 01 X 10 Male Connector Molex 3.96mm

ALL ELECT HR-10 .35

ON HAND

2 - 1X5 Connector Molex 3.96mm SCREW TERMINAL

AMAZON *

1 - CB4 - CIRCUIT BOARD - JLC PRO

------------------------------------------------------------

CHASSIS

1 - F1 - Fuse 1.5 Slo-Blo

ALL ELECT FSSB-1 .35

1 - F1H – FUSE HOLDER

JAMECO 2235882 .99

1 - P1 - Wall Plug and Cable

ON HAND

1 - SW1 – SPST

ALL ELECT STS-135 1.55

1 - T1 - Transformer single primary, dual secondary 110/28 V

MOUSER 1182G18 88.77

1) POWER SUPPLIES

+/- 15 VDC XMFR 1

+/- 7.5 V DC XMFR 1

+ 5.0 VDC

SCHEMATICS

CIR BOARDS

CABINET

2) TIMER / CLOCK

SEPARATE UNITS FROM MIXER DUE TO SPACE LIMITS

12 HOUR MOD 60 MOD 60 MOD 12

24 HOUR MOD 60 MOD 60 MOD 23

MAIN BOARD

SCHEMATIC

CIR BOARD

60 SEC/MIN MOD

SCHEMATIC

CIR BOARD

23 HOUR MOD

SCHEMATIC

CIR BOARD

12 HOUR MOD

SCHEMATIC

CIR BOARD

TIMER UNIT

DESIGN

SCHEMATIC

PROTO TYPE

CIR BOARD

RE-SET PANEL

DESIGN

SCHEMATIC

PROTO TYPE

CIR BOARD

3) DISPLAY BOARD

DESIGN

SCHEMATIC

PROTO TYPE

CIR BOARD

CABINET

PROTO TYPE

FINAL

4) HEADPHONE AMPLIFIER

DESIGN

SCHEMATIC

PROTO TYPE

CIRCUIT BOARD

5) CUE AMPLIFIER

CAN ALSO USE AS A TEST AMP WHILE BUILDING AUDIO BOARDS

DESIGN

SCHEMATICS

PROTO TYPE

CIRCUIT BOARDS

6) MONITOR SELECT

DESIGN

AVOID OLD STYLE SWITCHES, USE DIGITAL

SCHEMATIC

PROTO TYPE

CIR. BOARD

7) INPUT SELECT

DESIGN

AVOID OLD STYLE SWITCHES, USE DIGITAL

SCHEMATIC

PROTO TYPE

CIR. BOARD

8) AUDIO INPUT BOARD

DESIGN

RS-12 VERSION

SCHEMATIC

PROTO TYPE

CIR. BOARD

9) MONITOR BOARD

DESIGN BASED ON MONITOR SELECT DESIGN

SCHEMATIC

PROTO TYPE

CIR. BOARD

10)VU METER BOARD

SEPARATE UNIT ON SHELF

ONLY USED BECAUSE IT IS ALREADY BUILT

DESIGN

SCHEMATIC

PROTO TYPE

CIR BOARD

11) LED METERING

ON BOARD THE MIXER

USE RS-12 CIRCUIT REG LED'S OR BAR GRAPHS ????

DESIGN

SCHEMATICS

PROTO TYPE

CIRCUIT BOARD

12) POWER SUPPLY DISTRIBUTION BOARD ??

MAY BE NEEDED WITH MULTIPLE BOARDS ??

No comments:

Post a Comment